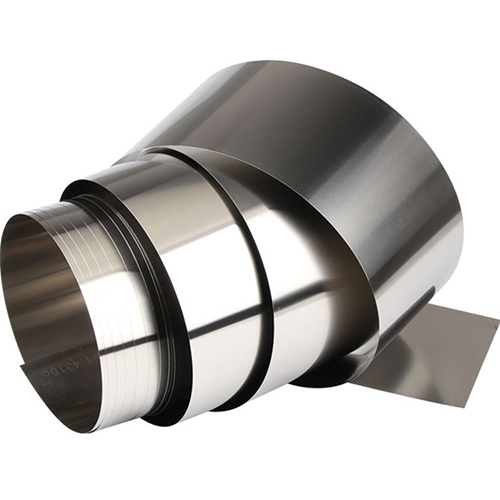

Letlapa la titanium, foil ea titanium e hloekileng haholo

Letlapa la titanium,bohloeki bo phahameng ba titanium foil,

Sehlopha sa 2, Sehlopha sa 5, Kereiti ea 7 le Kereiti ea 9, Kereiti, bohloeki bo phahameng ba titanium foil, Titanium ea bongaka, Letlapa la Titanium, Lisebelisoa tsa Tittanium Strip le Foil: Pure Titanium(CP) le Titanium alloy foil,

• Letlapa la Tittanium le Lisebelisoa tsa Foil: E hloekileng ea Titanium (CP) le Titanium alloy foil, Grade1,Sehlopha sa 2, Sehlopha sa 5, Kereiti ea 5,Kereiti ea 7 le Kereiti ea 9

• Liforomo: Letlapa le le leng, ka khoele, kapa holim'a spool.Ho na le tšebeletso ea ho roala

• Boemo:Botenya: ≥0.01mm : 20~1000mm, Length: Joalo ka Kopo

• Maemo:Cold rolled(Y)~Hot rolled(R)~Annealed (M)~Solid Status

• Maemo:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 joalo-joalo.

• Lisebelisoa:Lisebelisoa tsa elektronike, lik'hemik'hale, lioache, likhalase, mabenyane, thepa ea lipapali, mechini, lisebelisoa tsa plating, lisebelisoa tsa tikoloho, indasteri ea kolofo le e nepahetseng.

| Titanium Alloys Material Lebitso le Tloaelehileng | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Letlapa la Titaniumle foil:Haholo-holo re fana ka titanium Strip e hloekileng ea limaraka tsa Gr1, Gr2, Gr4;Bakeng sa titanium alloy Foil, Re fana haholo ka Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 le limaraka tse ling,Li hlahisoa motheong oa poleiti ea titanium e nang le serame se eketsehileng;ts'ebetso ea tlhahiso ea letlapa la titanium e rarahane le ho feta.Taolo ea deformation e thata haholoanyane ts'ebetsong ea rolling.E ka khaoloa ka boholo bo fapaneng ho ea ka litlhoko tsa moreki, e khutsufatsa haholo nako ea ho pepa.

♦ Sebopeho sa Titanium Strip Chemical ♦

| Kereiti | Sebopeho sa lik'hemik'hale, peresente ea boima ba 'mele (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lintlha Tse Ling Max.enngwe le enngwe | Lintlha Tse Ling Max.kakaretso | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanum Alloy Strip Thepa ea 'mele♦

| Kereiti | Lintho tsa 'mele | |||||||

| Matla a tšepe Min | Kotulo e nyane (0.2%, offset) | Elongation ka 4D Min (%) | Phokotso ea Sebaka Min (%) | Teko ea Bend(Radius of Mandrel) | ||||

| ksi | MPa | ksi | MPa | <1.8mm Botenya | 1.8-4.8mm ka botenya | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

•Sehlopha sa 1: Titanium e hloekileng, e batlang e le matla a tlase le ductility e phahameng.

•Sehlopha sa 2: Titanium e hloekileng e sebelisoang haholo.Motsoako o motle ka ho fetisisa oa matla

•Sehlopha sa 3: Titanium e matla e phahameng, e sebelisetsoang lipoleiti tsa Matrix ka har'a likhetla le li-heaters tsa mocheso

•Sehlopha sa 5: Alloy ea titanium e entsoeng ka ho fetisisa.Matla a phahameng ka ho fetisisa.ho hanyetsa mocheso o phahameng.

•Kereiti ea 7: Ho hanyetsa ho hoholo ha kutu maemong a fokotsehileng le a oxidizing.

•Sehlopha sa 9: Matla a phahameng haholo le ho hanyetsa ho bola.

•Sehlopha sa 12: Ho hanyetsa mocheso ho feta Titanium e hloekileng.Likopo tsa Kereiti ea 7 le Kereiti ea 11.

•Sehlopha sa 23: Titanium-6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy bakeng sa kopo ea ho kenngoa ha ho buuoa.

Sekonic Metals Technology Co., Ltd e fana ka poleiti ea titanium, molamu oa titanium, capillary ea titanium, screw screw, titanium fastener, terata ea titanium, linate tsa titanium, likarolo tse bōpehileng ... lihlahisoa le litšebeletso ka kopo ikopanye le rona, re lebeletse karabo ea hau