High Temperautre Spring Disc Spring Wave Spring

Mocheso o Phahameng oa Selemo:

Selemo ke karolo ea mochini e sebelisang elasticity ho sebetsa.Likarolo tse entsoeng ka thepa ea elastic li senyeha tlas'a ketso ea matla a ka ntle, 'me li khutlela sebopeho sa tsona sa pele ka mor'a ho tlosa matla a ka ntle.E boetse e sebelisoa e le "selemo".Ka kakaretso e entsoe ka tšepe ea selemo.Mefuta ea limela e rarahane ebile e fapane.

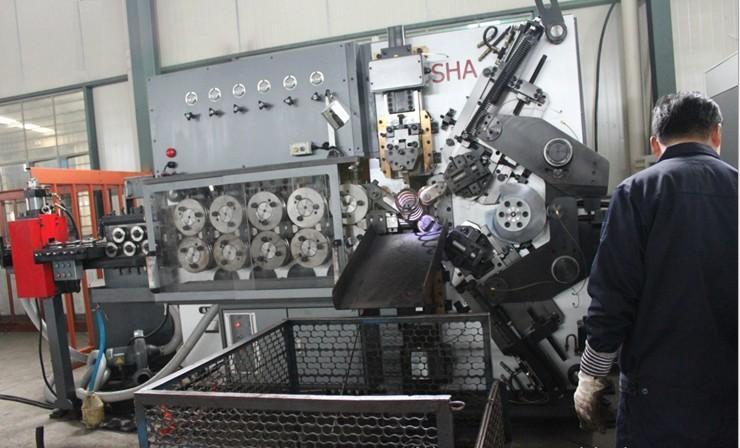

Khampani ea Rōna e Kopane le professonial Spring Factories Main Hlahisa le ho fana ka li-Spring tsa mocheso o phahameng

• Lisebelisoa tsa Selemo tsa Mocheso o Phahameng:

SUS304,SUS316, SUS631/17-7PH, SUS632/15-7Mo, 50CrVA, 30W4Cr2VA,

Inconel X-750, Tlhaloso: 718, Niconic90, Inoloy A286(SUH660)

• Mefuta ea Selemo:

→Compression Springs → Katoloso ea selemo

→Seruthwane sa Torsion →Seruthwana se Kobehang

♦ Selemo sa Leqhubu ♦ TsamaisaSelemo♦ Disc Spring

♦ Ring Spring ♦ Special-Shaped Spring, joalo-joalo

| Mefuta ea Lintho | Lebitso la Boitsebiso | Boholo ba mocheso oa Kopo°C |

| ts'epe e sa beng le mabali | SUS304/SUS316 | 200 |

| SUS631/17-7PH | 370 | |

| SUS632/15-7Mo | 470 | |

| Alloy spring tšepe | 50CrVA | 300 |

| 30W4Cr2VA | 500 | |

| Mocheso o phahameng oa nickel base alloy | Inoloy A286(GH2132) | 600 |

| Inconel X-750(GH4145) | 600 | |

| Inconel 718 (GH4169) | 690 | |

| Nimonic90(GH4090) | 800 (γ<0.2) | |

| GH4099 | 1000 (γ<0.1) |

♦♦♦ Diski Springs♦♦♦

Li sebelisoa haholo ho li-valve, li-flange, li-clutch, mariki, li-converter tsa torque, switch ea matla a phahameng a matla, ho tiisa bolt, tšehetso ea lipeipi, masimo a shockproof le a shockproof.ba hlahisitse ho latela DIN EN16983 (DIN2093).

Bophara ba ka ntle bo fapana ho tloha ho 6mm ho isa ho 1000mm.

Thepa e kenyeletsatšepe ea motsoako 51CrV4, tšepe ea carbon SK85, 1074;

• tšepe e sa hloekang ASTM301, 304, 316, 17-7PH, 17-4PH, 15-7Mo;

• Tšepe e sa keneleng mocheso H13, X30WCrV53, X22CrMoV12-1, X39CrMo17-1;

• Thepa e phahameng e hanyetsanang le mocheso oa tšepe e sa jeleng paate Inconel X750, Inconel X718, Nimonic 90, joalo-joalo.

♦♦♦ Lithaba tsa Leqhubu♦♦♦

Wave Spring ke tšepe e tšesaane e bōpehileng joaloka lesale e entsoeng ka maqhubu a mangata le liphula.Liliba tsa Wave li sebelisoa haholo ho li-motors, metjhini ea masela, lisebelisoa tsa hydraulic, likoloi le liindasteri tse ling.Setsi se seholo sa ho kenya le litlhaloso (boholo ba lebitso) ba kamore ea ho beleha li loketse.Kapa ka sekoting, sebaka sa ho kenya se senyenyane, 'me se na le mosebetsi o khethehileng oa ho fokotsa lerata le ho fokotsa ho sisinyeha.

Bophara ba ka ntle bo fapana ho tloha ho 6mm ho isa ho 1000mm.botenya bo tloha ho 0.4mm ho isa ho 5.0mm.

Tšireletso ea mafome

- Phosphating

- Mechanical galvanizing

- Nickel e pentiloe

- Jiaomei

Ba na le litšobotsi tsa deformation e nyenyane le mojaro o moholo.E boetse e na le likarolo tse latelang.

- Li-spring tsa disc li ka fumana litšobotsi tse fapaneng tsa mojaro ka mefuta e fapaneng ea inversion le ho fetana.

- Ha ho bapisoa le liliba tse ling, liliba tsa disc li nka sebaka se senyenyane.

- Ha lipampiri tse ngata li sebelisoa hammoho, phello ea damping ea eketseha.

- Ha e sebelisoa ka mokhoa o utloahalang, e ke ke ea senyeha kapa ea robeha.

- Bophelo bo bolelele ba mokhathala.

| Lisebelisoa tsa Selemo | Nako ea Mosebetsi | Matla a tšepe | Elastic Modulus KN//mm2 | Khemistri% | ||||||||||||||||||

| °C | N/mm2 | RT°C | 100°C | 200°C | 300°C | 400°C | 500°C | 600°C | C | Si | Mn | P | S | Cr | Ni | Ba bang | ||||||

| T8A SK85 | -50 ho +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.80-0.09 | ≤ 0.35 | ≤ 0.50 | ≤ 0.03 | ≤ 0.03 | ≤ 0.20 | ≤ 0.25 | Cu≤0.30 | |||||

| 50CrV4 SUP10 | -50 ho ea ho +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.47-0,55 | ≤ 0.4 | 0.71.1 | ≤ 0.025 | 0.025 | 0.9 1.2 | ≤ 0.4 | V:0.1 0.25Mo≤ 0.1 | |||||

| C75 | -50 ho +100 | 1200-1800 | 206 | 202 | - | - | - | - | - | 0.70-0,80 | 0.15-0,35 | 0.60 0.90 | ≤ 0.025 | 0.025 | ≤ 0.4 | ≤ 0.4 | Mo≤ 0.1 | |||||

| 60Si2Mn SUP6 | -50 ho ea ho +200 | 1200-1800 | 206 | 202 | 196 | - | - | - | - | 0.56-0.64 | 1.50-2.0 | 0.6 0.9 | ≤ 0.035 | 0.035 | ≤ 0.35 | ≤ 0.35 | ||||||

| X 10CrNi 18-8 SUS301 | -200 ho ea ho +200 | 1150-1500 | 190 | 186 | 180 | - | - | - | - | 0.05-0.15 | ≤ 2.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 16.0 19.0 | 6.0 9.5 | Mo≤ 0.08 | |||||

| X 5CrNi 18-10SUS304 | -200 ho ea ho +200 | 1000-1500 | 185 | 179 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 17.0 19.5 | 6.0 9.5 | N≤ 0.11 | |||||

| X 5CrNiMo 17-12-2 SUS316 | -200 ho ea ho +200 | 1000-1500 | 180 | 176 | 171 | - | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 2.0 | ≤ 0.045 | 0.015 | 16.5-18.5 | 10.0 13.0 | Mo:2.0-2.5N≤ 0.11 | |||||

| X 7CrNiAl 17-7 SUS631 | -200 ho ea ho +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 0.7 | ≤ 1.0 | ≤ 0.04 | 0.015 | 16.0 18.0 | 6.5 7.8 | Al:0.7-1.5 | |||||

| X5CrNiCuNb 16-4 SUS630 | -200 ho ea ho +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.07 | ≤ 1.0 | ≤ 1.0 | ≤ 0.035 | 0.03 | 15.0 17.0 | 3.0 5.0 | ||||||

| X8CrNiMoAl 15-7-2 | -200 ho ea ho +300 | 1150-1700 | 195 | 190 | 180 | 171 | - | - | - | ≤ 0.09 | ≤ 1.0 | ≤ 1.0 | ≤ 0.04 | 0.03 | 14.0 16.0 | 6.5 7.75 | Mo:2.0-3.0Al:0.75-1.5 | |||||

| Tšepe X39CrMo 17-1 | -50 ho ea ho +400 | 1200-1400 | 215 | 212 | 205 | 200 | 190 | - | - | 0.33-0.45 | ≤ 1.0 | ≤ 1.5 | ≤ 0.04 | 0.03 | 15.5 17.5 | ≤ 1.0 | Mo:0.7-1.3 | |||||

| X 22CrMoV 12-1 | -50 ho ea ho +500 | 1200-1400 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.18-0.24 | ≤ 0.5 | 0.4 0.9 | ≤ 0.025 | 0.015 | 11 12.5 | 0.3-0.8 | V:0.25-0,35Mo:0.8-1.2 | |||||

| X30WCRV53 SKD4 | -50 ho ea ho +500 | ≥ 1470 | 216 | 209 | 200 | 190 | 179 | 167 | - | 0.25-0,35 | 0.15-0.30 | 0.20 0.40 | ≤ 0.035 | 0.035 | 2.2 2.5 | ≤ 0.35 | V:0.5-0.7 W: 4-5 | |||||

| X40CrMoV5-1 SKD61 | -150 ho ea ho +600 | 1650-1990 | 206 | 200 | 196 | 189 | 186 | 158 | - | 0.32 0.40 | 0.8 1.20 | 0.20 0.50 | ≤ 0.030 | 0.030 | 4.75 5.50 | V:0.80-1.20Mo:1.1-.75 | ||||||

| Nickel Inconel X750 | -200 ho ea ho +600 | ≥ 1170 | 214 | 207 | 198 | 190 | 179 | 170 | 158 | ≤ 0.08 | ≤ 0.50 | ≤ 1.0 | ≤ 0.02 | 0.015 | 14.0 17.0 | ≥70 | Co≤ 1.0 Ti2.25-2,75 Fe 5.0-9.0 | |||||

| Inconel X718 | -200 ho ea ho +600 | ≥ 1240 | 199 | 195 | 190 | 185 | 179 | 174 | 167 | 0.02 0.08 | ≤ 0.35 | ≤ 0.35 | ≤ 0.015 | 0.015 | 17.0 21.0 | 50.0 55.0 | V≤ 1.0Mo:0.70-1.15 | |||||

| Nimoninike 90 | -200 ho ea ho +700 | ≥ 1100 | 220 | 216 | 208 | 202 | 193 | 187 | 178 | ≤ 0.13 | ≤ 1.0 | ≤ 1.0 | ≤ 0.03 | 0.015 | 18.0 21.0 | Bal | V15.0-21.0Mo:2.0-3.0 Al≤ 0.2 | |||||

♦♦♦ Lisebelisoa tsa Mocheso o Phahameng oa Selemo Likarolo: ♦♦♦

♦ 304 tšepe e sa hloekang

304 tšepe e sa hloekang e holofatsoa ke ho sebetsa ho batang ho ntlafatsa thepa ea eona e otlolohileng.E ke ke ea thatafatsoa ke phekolo ea mocheso.E tla hlahisa magnetism nakong ea mosebetsi o batang.304 tšepe e sa jeleng paate e na le khanyetso e matla ea kutu le thepa e ntle ea 'mele.

316 tšepe e sa hloekang e holofatsoa ke ho sebetsa ho batang ho ntlafatsa thepa ea eona ea rekere, 'me e ke ke ea thatafatsoa ke kalafo ea mocheso.E tla hlahisa magnetism nakong ea mosebetsi o batang.316 tšepe e sa hloekang e na le molybdenum, e nang le khanyetso e matla ea ho senya ho feta 304 tšepe e sa hloekang, 'me e khona ho hanela ho bola lits'ebetsong tsa lik'hemik'hale.

17-7PH e hanyetsanang le kutu e tšoanang le 304 tšepe e sa hloekang, e ka fokotsoang ke phekolo ea mocheso le ho thatafala ha pula.E na le matla a phahameng le ho fana ka matla.Ts'ebetso ea mokhathala e betere ho feta tšepe e sa hloekang ea 304 le 65Mn carbon steel.E boetse e na le elasticity e ntle tlasa tikoloho ea ℃.

♦15-7Mo (GH632, 0Cr15Ni7Mo2Al)

15-7MoHa e na le khanyetso e ts'oanang ea kutu ho 316 tšepe e sa hloekang.E ka fetisoa ke phekolo ea mocheso le ho thatafala ha pula.E na le matla a phahameng a ho tsitsa le ho fana, 'me ts'ebetso ea eona ea mokhathala e betere ho feta tšepe e sa hloekang ea 316 le 65Mn carbon steel.E boetse e na le elasticity e ntle tlasa tikoloho ea ℃.

Inconel X-750 ke "nickel-based precipitation hardening deformation superalloy".Haholo-holo e sebelisa r'phase joalo ka mohato o thatafatsang oa botsofali.Mocheso o khothalelitsoeng o ka tlase ho 540 ℃.Alloy e na le khanyetso e itseng ea kutu le khanyetso ea oxidation, 'me e na le ts'ebetso e itseng ea mocheso o tlase.

Inconel 718 ke "nickel-based precipitation" e thatafatsang deformation superalloy.Mocheso o khothalletsoang ke -253--600 ℃.Alloy e na le matla a phahameng ka tlase ho 600 ° C, e na le ho hanyetsa mokhathala o motle, ho hanyetsa mahlaseli, ho hanyetsa oxidation le ho hanyetsa kutu, hammoho le ts'ebetso e ntle ea ts'ebetso le botsitso ba nako e telele ea sebopeho.

Alloy A-286 ke precipitatio e thehiloeng ka tšepen alloy e thatafatsang ea mocheso o phahameng.Mocheso o khothalletsoang oa ho sebetsa o ka tlase ho 540 ℃.Alloy e na le matla a phahameng a mocheso a phahameng le a tlase le botsitso ba nako e telele, ho hanyetsa kutu e ntle le ts'ebetso ea ho senyeha ha mocheso, 'me e na le polasetiki e ntle ea ho sebetsa le ts'ebetso e khotsofatsang ea welding.