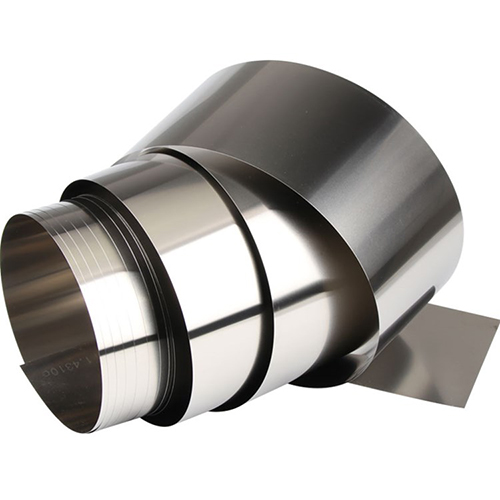

Letlapa la Titanium le Foil

• Letlapa la Tittanium le Lisebelisoa tsa Foil:E hloekileng ea Titanium (CP) le foil ea alloy ea Titanium,Kereiti ya 1, Kereiti ya 2, Kereiti ya 5, Kereiti ya 5, Kereiti ya 7 le 9

• Liforomo: Letlapa le le leng, ka khoele, kapa holim'a spool.Ho na le tšebeletso ea ho roala

• Boemo:Botenya: ≥0.01mm : 20~1000mm, Length: Joalo ka Kopo

• Maemo:Cold rolled(Y)~Hot rolled(R)~Annealed (M)~Solid Status

• Maemo:ASTM B265, AMS 4911, AMS 4902, ASTM F67, ASTM F136 joalo-joalo.

• Lisebelisoa:Lisebelisoa tsa elektronike, lik'hemik'hale, lioache, likhalase, mabenyane, thepa ea lipapali, mechini, lisebelisoa tsa plating, lisebelisoa tsa tikoloho, indasteri ea kolofo le e nepahetseng.

| Titanium Alloys Material Lebitso le Tloaelehileng | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

Letlapa la Titanium le Foil:Haholo-holo re fana ka titanium Strip e hloekileng ea limaraka tsa Gr1, Gr2, Gr4;Bakeng sa titanium alloy Foil, Re fana haholo ka Gr5, Gr7, Gr9, Gr11, Gr12, Gr16, Gr23 le limaraka tse ling,Li hlahisoa motheong oa poleiti ea titanium e nang le serame se eketsehileng;ts'ebetso ea tlhahiso ea letlapa la titanium e rarahane le ho feta.Taolo ea deformation e thata haholoanyane ts'ebetsong ea rolling.E ka khaoloa ka boholo bo fapaneng ho ea ka litlhoko tsa moreki, e khutsufatsa haholo nako ea ho pepa.

♦ Sebopeho sa Titanium Strip Chemical ♦

| Kereiti | Sebopeho sa lik'hemik'hale, peresente ea boima ba 'mele (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lintlha Tse Ling Max.enngwe le enngwe | Lintlha Tse Ling Max.kakaretso | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Sekhahla sa Titanum AlloyLintho tsa 'mele♦

| Kereiti | Lintho tsa 'mele | |||||||

| Matla a tšepe Min | Ho hlahisa matlaMets (0.2%, e fokotsehile) | Elongation ka 4D Min (%) | Phokotso ea Sebaka Min (%) | Teko ea Bend(Radius of Mandrel) | ||||

| ksi | MPa | ksi | MPa | <1.8mm Botenya | 1.8-4.8mm ka botenya | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 | 4.5T | 5.0T |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 | 2.5T | 3.0T |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 | 1.5T | 2.0T |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 | 2.0T | 2.5T |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 | 2.0T | 2.5T |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 | 4.5T | 5.0T |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

•Sehlopha sa 1: Titanium e hloekileng, e batlang e le matla a tlase le ductility e phahameng.

•Sehlopha sa 2: Titanium e hloekileng e sebelisoang haholo.Motsoako o motle ka ho fetisisa oa matla

•Sehlopha sa 3: Titanium e matla e phahameng, e sebelisetsoang lipoleiti tsa Matrix ka har'a likhetla le li-heaters tsa mocheso

•Sehlopha sa 5: Alloy ea titanium e entsoeng ka ho fetisisa.Matla a phahameng ka ho fetisisa.ho hanyetsa mocheso o phahameng.

•Kereiti ea 7: Ho hanyetsa ho hoholo ha kutu maemong a fokotsehileng le a oxidizing.

•Sehlopha sa 9: Matla a phahameng haholo le ho hanyetsa ho bola.

•Sehlopha sa 12: Ho hanyetsa mocheso ho feta Titanium e hloekileng.Likopo tsa Kereiti ea 7 le Kereiti ea 11.

•Sehlopha sa 23: Titanium-6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy bakeng sa kopo ea ho kenngoa ha ho buuoa.