Feme ea tlhahiso ea mohloli oa Titanium mesh.Titanium terata mesh, Mesh ea bongaka ea titanium

Feme ea tlhahiso ea mohloli oa Titanium mesh.Letlooa la Titanium, Mesh ea bongaka ea titanium,

Sehlopha sa 2, Sehlopha sa 5, Kereiti ya11.Kereiti ya12.Sehlopha sa 16, Kereiti ya23, Sehlopha sa7, Sehlopha sa9, Kereiti, TA2, TALA, TC4,

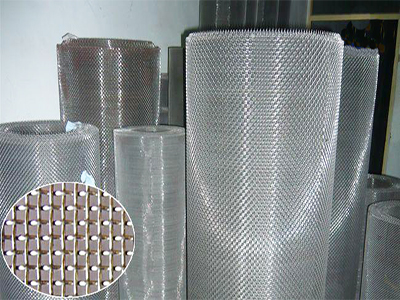

Titanium Mesh:Titanium Mesh e entsoeng ke lithapo tsa Titanium Alloys, k'hamphani ea rona e kopantsoe le feme ea Mesh e holisang mefuta ea lihlahisoa ho isa lihlahisoa tsa mesh le lihlahisoa tse ling tse entsoeng.re na le boiphihlelo ba lilemo tse ngata tsa tlhahiso ea terata, 'me letlooeng la titanium le hlahisoang le na le litšobotsi tsa ts'ebetso e tsitsitseng le e ntle ea ho sefa.

• Mefuta:

→ Letlooa le lohiloeng le bonolo → Letlooa le lohiloeng

→ Mesh ea weave e entsoeng esale pele → letlooeng la Dutch

• Tlhaloso: 1 mesh-100 mesh

Litekanyetso tsa ASTM li lateloa tlhahisong ea meshes ea terata.Litlhaloso tse fumanehang tsa mesh li tloha ho tse boima haholo ho isa ho tse ntle haholo.Mesh e boima ka ho fetisisa e entsoe ka terata ea 8.0mm ha letlooeng le letle ka ho fetisisa le entsoe ka terata ea 0.03mm e nang le 360mesh/inch.

• Lisebelisoa:Mesh ea terata ea Titanium e ka sebelisoa litsing tse thibelang mocheso o phahameng, kaho ea likepe, tlhahiso ea sesole, li-filters tsa lik'hemik'hale, li-filters tsa mochini, matlooa a sireletsang motlakase, li-filters tsa metsi a leoatleng, matlooa a mocheso a phahameng a mocheso oa sebōpi sa mocheso oa sebōpi, lisebelisoa tsa oli, ts'ebetso ea lijo, ho hloekisa ka bongaka.

| Titanium Alloys Material Lebitso le Tloaelehileng | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Alloys Chemical Composition ♦

| Kereiti | Sebopeho sa lik'hemik'hale, peresente ea boima ba 'mele (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lintlha Tse Ling Max.enngwe le enngwe | Lintlha Tse Ling Max.kakaretso | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanum Alloy Physical Properties ♦

| Kereiti | Lintho tsa 'mele | |||||

| Matla a tšepe Min | Ho hlahisa matla Mets (0.2%, e fokotsehile) | Elongation ka 4D Min (%) | Phokotso ea Sebaka Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

Letlooa la Titanium le sebelisoa haholo-holo bakeng sa asiti, maemo a tikoloho a alkali a hlahloba maemo le ho sefa kapa khase, ho hloekisa metsi le karohano e meng ea mecha ea phatlalatso.Ho na le mekhoa e mene ea ho loha ka mokhoa o hlakileng, twill weave, pre – crimp weave le Dutch weave.Saikang Metal Technology Co., Ltd. e ikemiseditse ho fa bareki dihlahiswa/ditshebeletso tsa boleng.Haeba o kgahlehela dihlahiswa le ditshebeletso tsa rona, ka kopo ikopanye le rona mme o lebelle karabo ya hao ka thabo.