Titanium capillary tubes bakeng sa tšebeliso ea bongaka

Titanium capillary tubes bakeng sa tšebeliso ea bongaka,

CP-Ti, Tube e hloekileng ea Titanium Capillary, Ti-0.20Pd,Ti-3AL-2.5V,Ti-0.15Pd,Ti-0.3Mo-0.8NiTi-0.05Pd, Ti-6AI-4VELI, Titanium Capillary Tube,

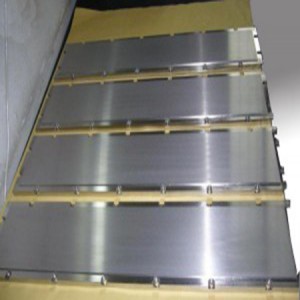

Titanium Capillary Tube:Ka lebaka la li-alloys tsa Titanium, bolelele ba bohloeki ba titanium bo ka fihla ho 50-60%, 'me ho fokotseha ha sebaka ho ka fihla ho 70-80%.Seo se etsa tlhahiso ea titanium capillary tube.Ho theha le ho roala li-ingots tsa bobeli tse qhibilihisang tsa titanium ka har'a li-tube billets, ebe o otlolla tube billet ka makhetlo a 'maloa ho fihlela tube ea capillary ea titanium e thehoa.Ka lebaka la ho lumellana hantle le 'mele oa motho le ho hanyetsa kutu, titanium capillary tube e sebelisoa haholo indastering ea bongaka, ho kenyeletsoa li-implants tsa' mele oa motho, lisebelisoa tsa bongaka likarolo tse nepahetseng tsa ka hare, joalo-joalo.

• Lisebelisoa tsa Tittanium Capillary Tube: Pure Titanium, Grade1, Grade 2, Grade 5, Grade 5, Grade7 , Grade9, Grade11, Grade12, Grade 16, Grade23 ect

• BoemoOD: 0.2 ~ 8mm, WT: 0.015 ~ 0.5mm, Length≤6000mm

• Maemo:ASTM B338, ASTM B337, ASTM B861, ASTM B862 joalo-joalo

| Titanium Alloys Material Lebitso le Tloaelehileng | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Capillary Tube Chemical Composition ♦

| Kereiti | Sebopeho sa lik'hemik'hale, peresente ea boima ba 'mele (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lintlha Tse Ling Max.enngwe le enngwe | Lintlha Tse Ling Max.kakaretso | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5 6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦ Titanium Capillary Tube Physical Properties ♦

| Kereiti | Lintho tsa 'mele | |||||

| Matla a tšepe Min | Ho hlahisa matla Mets (0.2%, e fokotsehile) | Elongation ka 4D Min (%) | Phokotso ea Sebaka Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦ ♦ ♦ Titanium Alloy Materials Features: ♦ ♦ ♦

•Sehlopha sa 1:Titanium e hloekileng, matla a batlang a le tlase le ductility e phahameng.

• Sehlopha sa 2:Titanium e hloekileng e sebelisoang haholo.Motsoako o motle ka ho fetisisa oa matla

• Sehlopha sa 3:Titanium e matla e phahameng, e sebelisetsoang lipoleiti tsa Matrix ka khetla, li-exchanger tsa mocheso oa tube

• Sehlopha sa 5:Ka ho fetisisa entsoeng titanium motsoako.E phahameng ka ho fetisisa matla a phahameng le ho hanyetsa mocheso.

• Sehlopha sa 7:Khanyetso e phahameng ea kutu maemong a ho fokotsa le oxidizing.

• Kereiti ea 9:Matla a phahameng haholo le khanyetso ea kutu.

• Kereiti ea 12:Ho hanyetsa mocheso ho feta Titanium e hloekileng.e sebediswa bakeng sa Kereiti ya 7 le Kereiti ya 11.

•Sehlopha sa 23:Titanium-6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy bakeng sa ts'ebeliso ea ho kenngoa ha ho buuoa.

Lihlahisoa tse ka sehloohong tsa titanium capillary ke: tube ea titanium e se nang moeli, tube e kholo ea caliber titanium, titanium tube bakeng sa mochine oa mocheso, joalo-joalo, e ka etsoa ka litlhaloso tse fapaneng, setsebi sa ho etsa titanium tube lilemo tse 20 tsa boleng ba ts'ebetso ea litsebi, phepelo e lekaneng.