AMS ASME ASTM bakeng sa li-inconel625 alloy navigators

AMS ASME ASTM bakeng sa basesisi ba inconel625 alloy,

625 Alloy,Inconel 625 Bars ,Inconel 625 Rods,Inconel 625 sheet ,Inconel 625 plate,Inconel 625 strip,Inconel 625 coil,

Mabitso a Tloaelehileng a Khoebo: Inconel 625, UNS NO6625, Nickel Alloy 625, Alloy 625, Nickel 625, W.Nr.2.4856

Inconel Alloy 625 ha e na matla a makenete, ha ho kutu le ho hanyetsa oxidation, nickel-chromium alloy.Matla a phahameng a Inconel 625 ke phello ea ho thatafala ha molybdenum le niobium motheong oa nickel chromium ea alloy.Inconel 625 e na le khanyetso e matla ho mefuta e mengata e fapaneng ea tikoloho e senyang ka mokhoa o sa tloaelehang ho kenyelletsa litlamorao tsa mocheso o phahameng joalo ka oxidation le carburization.Matla a eona a ikhethang le ho tiea ha mocheso ho tloha ho mocheso oa cryogenic ho ea ho mocheso o phahameng ho fihla ho 2000 ° F (1093 ° C) li nkiloe haholo-holo ho tsoa liphellong tse tiileng tsa litšepe tse refractory Columbium le molybdenum ka matrix a nickel-chromium.

Inconel 625 Sebopeho sa Lik'hemik'hale

| % | Ni | Cr | Fe | Mo | Nb+Ta | Co | C | Mn | Si | S | Al | Ti | P |

| Min. | 58.0 | 20.0 | - | 8.0 | 3.15 | - | - | - | - | - | - | - | - |

| Max. | - | 23.0 | 5.0 | 10.0 | 4.15 | 1.0 | 0.1 | 0.5 | 0.5 | 0.015 | 0.4 | 0.4 | 0.015 |

Inconel 625 Thepa ea 'Mele

| Botenya | 8.4g/cm³ |

| Sebaka se qhibilihang | 1290-1350 ℃

|

Inconel 625 Thepa e Tloaelehileng ea Mechini

| Boemo | Matla a tšepe Rm N/mm² | Ho hlahisa matla Rp 0. 2N/mm² | Elongation Joalo ka % | Ho thatafala ha Brinell HB |

| Phekolo ea tharollo | 827 | 414 | 30 | ≤220 |

Inconel 625 Maemo le Litlhaloso

AMS 5599, AMS 5666, AMS 5837, ASME SB 443 Gr 1, ASME SB 446 Gr 1, ASTM B 443 Gr 1, ASTM B 446 Gr 1, EN 2.4856, ISO 15156-3, NACE M3R, NACE M3

UNS N06625, Werkstoff 2.4856

| Mohala | Leqephe | Hlobola | Molamu | Pipe | |

| AMS 5599, AMS 5666,AMS 5837, AMS 5979,ASTM B443 | ASTM B443 | AMS 5599, AMS 5979,ASTM B443 | ASTM B 446 SAE/AMS 5666, VdTÜV 499 | Pipe e se nang Seam | Pipe e cheselitsoeng |

| ASTM B 444/B 829 & ASME SB 444/SB 829SAE/AMS 5581 | ASTM B704/B751 ASME SB704/SB 751ASTM B705/B 775 , ASME SB 705/SB 775 | ||||

Inconel 625 Lihlahisoa tse fumanehang ka Metals ea Sekonic

Inconel 625 Bars & Rods

Li-bars tse chitja/Flat bars/Hex bars, Size From 8.0mm-320mm, E sebelisetsoa liboutu, li-fastners le likarolo tse ling

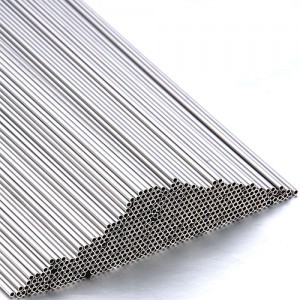

Inconel 625 terata ea ho tjheseletsa

Fana ka terata ea welding le terata ea selemo ka mokhoa oa khoele le bolelele bo sehiloeng.

Inconel 625 lakane & poleiti

Bophara ho fihla ho 1500mm le bolelele ho fihla ho 6000mm, Botenya ho tloha 0.1mm ho isa 100mm.

Inconel 625 tube e se nang seam & pipe e cheselitsoeng

Boholo ba litekanyetso le boholo bo hlophisitsoeng bo ka hlahisoa ke rona ka mamello e nyane

Inconel 625 strip & coil

Boemo bo bonolo le boemo bo thata bo nang le bokaholimo bo khanyang ba AB, bophara ho fihla ho 1000mm

Inconel 625 Fasteners

Alloy 625 re ka fana ka liboutu, linate le li-fasteners tse ling joalo ka litlhoko tsa bareki

Inconel 625 likarolo :

1.Matla a phahameng a ho phatloha

2.Oxidation e hanyetsana le 1800°F

3.Ho hanyetsa mokhathala o motle

4.Excellent weldability

5.Outstanding hanyetsa ho chloride pitting le crevice kutu

6.Immune ho chloride ion stress corrosion cracking

7.E hanana le metsi a leoatle tlas'a maemo a phallang le a tsitsitseng le tlas'a litšila

Inconel 625 Sebaka sa kopo:

•Litsamaiso tsa ho tsamaisa lifofane

•Sistimi ea ho felloa ke matla enjene ea jet

•Sistimi ea enjene ea thrust-reverser

•Li-bellows le manonyeletso a ho atolosa

•Mehele ea turbine shroud

•Li-flare stacks

•Likarolo tsa metsi a leoatle

•Lisebelisoa tsa ts'ebetso ea lik'hemik'hale tse sebetsanang le li-acid tse tsoakiloeng ka bobeli le ho fokotsa.

Liforomo tsa Lihlahisoa tsa Khamphani ea rona

Li-Bars & Rods

Inconel / Hastelloy/ Monel/ Haynes 25/ Titanium

Seamless Tube & Welded Tube

Nickel/ Titanium Alloy tubes, U-bend /heat exchange tube

Bolt & Nuts

Inconel 601/ Hastelloy C22/Inconel x750/Inconel 625 ect

Leqephe le Lipoleiti

Hastelloy/Inconel/Incoloy/Cobalt/Tianium

Hlobola & Foil

Hastelloy/Inconel/invar/ Li-alloys tse bonolo tsa makenete ect

Libaka tsa Mocheso o Phahameng

Inconel 718/Inconel x750/ Nimonic 80A

Mohala & Welding

Cobalt Alloy terata, Nickel alloy terata, Tianium Alloy terata

Li-Flange tse khethehileng tsa Alloy

Monel 400/ Hastelloy C276/ Inconel 718/ Titanium

Oli Tube Hanger

Inconel x750/ Inconel 718 /Monel 400 ect

Li-alloys tse thehiloeng ho Nickel

Lisebelisoa tsa Welding

Li-alloys tse thehiloeng ho Cobalt

Litšepe Tse Khethehileng

Lisebelisoa tsa Precision

Lisebelisoa tsa Titanium

U batla ho ithuta ho eketsehileng kapa ho fumana quote?

Kena ka Touch

625 alloy e entsoe ka thepa efe?Alloy e thehiloeng ho nickel e nang le Ni - Cr - Mo e phahameng.

Motsoako oa lik'hemik'hale oa Alloy 625: Chromium (Cr) 20.0-23.0, Iron (Fe)< 5.0, (Al) & lt;0.4, Silicon (Si)< 0.50 manganese (Mn)< 0.50, Nickel (Ni)258, sulphur (S)< 0.015, Cobalt (Co)< 1.0,(Mo)8.0-10.0, Titanium (Ti)< 0.4, Phosphorus (P)< 0.015,(Nb) 3.15-4.15, Khabone (C)< 0.01.

625 Alloy e na le oxidation e ntle haholo le ho hanyetsa kutu, matla a makatsang le ho tiea, ho hanyetsa mokhathala o matla, sebopeho se phahameng le ho cheseha ho hoholo.E ka boloka matla le ho tiea ha eona kae kapa kae ho tloha mocheso o tlase ho isa ho 2000 ° F.Ka lebaka la ho thatafala ka potlako ha motsoako oa 625, palo e kholo ea serame e ka 'na ea hloka hore ho be le annealing nakong eohle ea ho etsa serame.Alloy e sebelisoa hangata lienjineng tsa jet le lits'ebetsong tse ling tsa sefofane.