Mohala oa Titanium

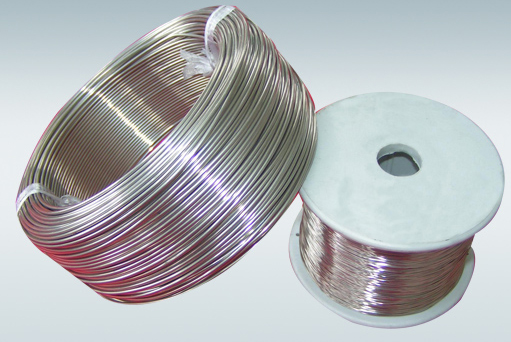

Mohala oa TitaniumHangata terata ea titanium e sebelisoa bakeng sa ho tjheseletsa, liforeimi, li-implants tsa ho buoa, mokhabiso, mochine o leketlileng oa electroplating.E sebelisoa ha ho etsoa phofo ea spherical titanium.

Tšebeliso ea terata ea "titanium" kapa "Titanium slab" ka har'a hlobo ho sebetsa, ka lebaka la phello ea ho hula, "titanium bar" e senyeha tlas'a mocheso o phahameng ha o feta ka lesoba la hlobo.Karolo ea sefapano e fokotsehile, 'me bolelele bo eketseha.Ho otlolla sebakeng se futhumetseng ho thusa ho felisa khatello ea maikutlo le ho ntlafatsa polasetiki ea lithapo tsa titanium.E ntlafatsa ka nepo ho nepahala ha terata ea titanium, le pheletso ea bokaholimo, e ka fihlelang ts'ebetso e phethahetseng e felletseng.

• Lisebelisoa tsa Wire tsa Tittanium: Kereiti ea1, Kereiti ea 2, Kereiti ea 5, Kereiti ea 5, Kereiti ea7, Kereiti ea9, Kereiti ea11, Kereiti ea12, Kereiti ea 16, Kereiti ea23 ect

• Liforomo tsa Mohala: Spool ka Coil, Cut length/Otlolohile

• Diameter: 0.05mm-8.0mm

• Maemo:Tharollo e Annealed ,Hot rolling, Otlolla

• Bokaholimo:Pickling White,Bright polished, Acid e hlatsoitsoe, Black oxide

• Maemo:ASTM B863, AWS A5.16, ASTM F67, ASTM F136 joalo-joalo

| Titanium Alloys Material Lebitso le Tloaelehileng | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Sebopeho sa Titanium Wire Chemical ♦

| Kereiti | Sebopeho sa lik'hemik'hale, peresente ea boima ba 'mele (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lintlha Tse Ling Max.enngwe le enngwe | Lintlha Tse Ling Max.kakaretso | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5-6.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Titanum Alloy WireThepa ea 'Mele ♦

| Kereiti | Lintho tsa 'mele | |||||

| Matla a tšepe Min | Ho hlahisa matla Mets (0.2%, e fokotsehile) | Elongation ka 4D Min (%) | Phokotso ea Sebaka Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Lisebelisoa tsa Titanium Alloy Likarolo: ♦♦♦

•Sehlopha sa 1: Titanium e hloekileng, e batlang e le matla a tlase le ductility e phahameng.

•Sehlopha sa 2: Titanium e hloekileng e sebelisoang haholo.Motsoako o motle ka ho fetisisa oa matla

•Sehlopha sa 3: Titanium e matla e phahameng, e sebelisetsoang lipoleiti tsa Matrix ka har'a likhetla le li-heaters tsa mocheso

•Sehlopha sa 5: Alloy ea titanium e entsoeng ka ho fetisisa.Matla a phahameng ka ho fetisisa.ho hanyetsa mocheso o phahameng.

•Sehlopha sa 9: Matla a phahameng haholo le ho hanyetsa ho bola.

•Sehlopha sa 12: Ho hanyetsa mocheso ho feta Titanium e hloekileng.Likopo tsa Kereiti ea 7 le Kereiti ea 11.

•Sehlopha sa 23: Titanium-6Aluminium-4Vanadium bakeng sa ts'ebeliso ea ho kenngoa ha opereishene.