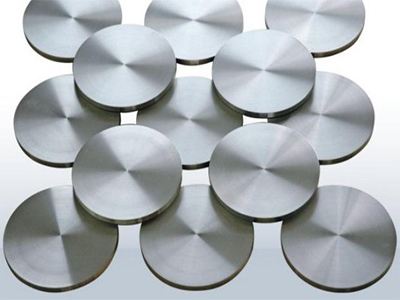

Sesepa sa Titanium

Sesepa sa TitaniumHangata e sebelisoa ho etsa mochine oa titanium flange kapa tubesheet ea Titanium bakeng sa lisebelisoa tsa mocheso oa mocheso.

Joaloka k'hamphani e nang le lilemo tse fetang 20 tsa phihlelo ea tlhahiso, re na le letoto la mekhoa e matla ea ho qhekella le buka ea ts'ebetso, ho kenyelletsa le mehato ea ho futhumatsa, nako ea ho futhumatsa le nako ea ho boloka mocheso.Mochini oa 35MN le 16MN oa ho qhekella ka potlako o netefalitse ho qhekella hangata ka har'a mocheso o loketseng.'Me theknoloji ea ho qapa e ka fetola sebopeho sa' mele sa titanium disc.E ntlafalitse haholo boleng ba titanium disc level.

• Lisebelisoa tsa Disc tsa Tittanium: Pure Titanium, Grade1, Grade 2, Grade 5, Grade 5, Grade7 , Grade9, Grade11, Grade12, Grade 16, Grade23 ect

• Liforomo: Boemo ba Maemo kapa joalo ka ha bareki ba taka.

• Boemo: OD: 150 ~ 1500mm, Botenya: 35 ~ 250mm, E hlophisitsoe

• Maemo:ASTM B265, ASTM B381

• Tlhahlobo:Teko ea sebopeho sa lik'hemik'hale→ Teko ea thepa ea 'mele → Tlhahlobo ea Macroscopic → Ho lemoha mefokolo ea Ultrasonic → Tlhahlobo ea bofokoli ba chebahalo

| Titanium Alloys Material Lebitso le Tloaelehileng | ||

| Gr1 | UNS R50250 | CP-Ti |

| Gr2 | UNS R50400 | CP-Ti |

| Gr4 | UNS R50700 | CP-Ti |

| Gr7 | UNS R52400 | Ti-0.20Pd |

| G9 | UNS R56320 | Ti-3AL-2.5V |

| G11 | UNS R52250 | Ti-0.15Pd |

| G12 | UNS R53400 | Ti-0.3Mo-0.8Ni |

| G16 | UNS R52402 | Ti-0.05Pd |

| G23 | UNS R56407 | Ti-6Al-4V ELI |

♦ Titanium Disc Sebopeho sa lik'hemik'hale ♦

| Kereiti | Sebopeho sa lik'hemik'hale, peresente ea boima ba 'mele (%) | ||||||||||||

| C (≤) | O (≤) | N (≤) | H (≤) | Fe (≤) | Al | V | Pd | Ru | Ni | Mo | Lintlha Tse Ling Max.enngwe le enngwe | Lintlha Tse Ling Max.kakaretso | |

| Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr4 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | - | - | - | - | 0.1 | 0.4 |

| Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.56.75 | 3.5 4.5 | - | - | - | - | 0.1 | 0.4 |

| Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | - | - | 0.12 0.25 | - | 0.12 0.25 | - | 0.1 | 0.4 |

| Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5 3.5 | 2.0 3.0 | - | - | - | - | 0.1 | 0.4 |

| Gr11 | 0.08 | 0.18 | 0.03 | 0.15 | 0.2 | - | - | 0.12 0.25 | - | - | - | 0.1 | 0.4 |

| Gr12 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | - | - | 0.6 0.9 | 0.2 0.4 | 0.1 | 0.4 |

| Gr16 | 0.08 | 0.25 | 0.03 | 0.15 | 0.3 | - | - | 0.04 0.08 | - | - | - | 0.1 | 0.4 |

| Gr23 | 0.08 | 0.13 | 0.03 | 0.125 | 0.25 | 5.5 6.5 | 3.5 4.5 | - | - | - | - | 0.1 | 0.1 |

♦Sesepa sa TitanumThepa ea 'Mele ♦

| Kereiti | Lintho tsa 'mele | |||||

| Matla a tšepe Min | Ho hlahisa matla Mets (0.2%, e fokotsehile) | Elongation ka 4D Min (%) | Phokotso ea Sebaka Min (%) | |||

| ksi | MPa | ksi | MPa | |||

| Gr1 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr2 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr4 | 80 | 550 | 70 | 483 | 15 | 25 |

| Gr5 | 130 | 895 | 120 | 828 | 10 | 25 |

| Gr7 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr9 | 90 | 620 | 70 | 483 | 15 | 25 |

| Gr11 | 35 | 240 | 20 | 138 | 24 | 30 |

| Gr12 | 70 | 483 | 50 | 345 | 18 | 25 |

| Gr16 | 50 | 345 | 40 | 275 | 20 | 30 |

| Gr23 | 120 | 828 | 110 | 759 | 10 | 15 |

♦♦♦ Lisebelisoa tsa Titanium Alloy Likarolo: ♦♦♦

•Sehlopha sa 1: Titanium e hloekileng, e batlang e le matla a tlase le ductility e phahameng.

•Sehlopha sa 2: Titanium e hloekileng e sebelisoang haholo.Motsoako o motle ka ho fetisisa oa matla

•Sehlopha sa 3: Titanium e matla e phahameng, e sebelisetsoang lipoleiti tsa Matrix ka har'a likhetla le li-heaters tsa mocheso

•Sehlopha sa 5: Alloy ea titanium e entsoeng ka ho fetisisa.Matla a phahameng ka ho fetisisa.ho hanyetsa mocheso o phahameng.

•Kereiti ea 7: Ho hanyetsa ho hoholo ha kutu maemong a fokotsehileng le a oxidizing.

•Sehlopha sa 9: Matla a phahameng haholo le ho hanyetsa ho bola.

•Sehlopha sa 12: Ho hanyetsa mocheso ho feta Titanium e hloekileng.Likopo tsa Kereiti ea 7 le Kereiti ea 11.

•Sehlopha sa 23: Titanium-6Aluminium-4Vanadium ELI (Extra Low Interstitial) Alloy bakeng sa kopo ea ho kenngoa ha ho buuoa.