MONEL Alloy K-500 (UNS N05500/ WR2.4375) ke motsoako oa koporo oa nickel-copper o kopanyang melemo ea ho hanyetsa kutu e babatsehang ka matla a maholo le ho thatafala ha MONEL alloy 400. Aluminium le titanium li ile tsa kenngoa setsing sa nickel-copper le ho futhumala. tlas'a maemo a laoloang ho fokotsa likaroloana tsa submicroscopic Ni3 (Ti, AI) ho pholletsa le setsi sa nickel-copper, kahoo ho ntlafatsa matrix a tshebetso.Tšebeliso ea mosebetsi o chesang ho finyella phello ea pula hangata e bitsoa ho tsofala ho thatafatsa kapa ho tsofala.

Lisebelisoa tse tloaelehileng tsa lihlahisoa tsa MONEL alloy K-500 ke liketane le li-cable fasteners le liliba.

Litšebeletso tsa Marine: Likopano tsa pompo le li-valve,

Phekolo ea lik'hemik'hale: ts'ebetso ea pulp tlhahiso ea pampiri bakeng sa likhahla tsa ngaka le li-scrapers;

Ho cheka seliba sa oli le lisebelisoa, shaft ea pompo le impeller, matlo a se nang makenete, phahamiso ea polokeho le valve ea oli le tlhahiso ea khase ea tlhaho;Le li-sensor le likarolo tse ling tsa lisebelisoa tsa elektroniki.

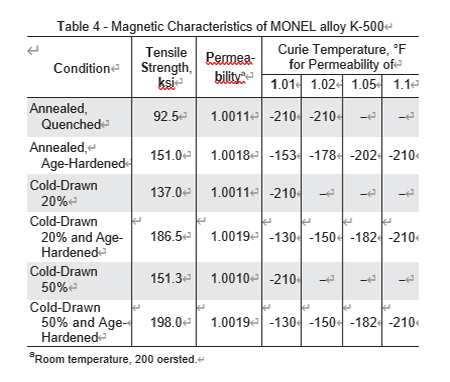

E 'ngoe ea thepa ea Monel K500 alloy ke hore ha e na matla a makenete, leha e le ka mocheso o tlase haholo.Leha ho le joalo, hoa khoneha ho theha lesela la magnetic holim'a thepa nakong ea ts'ebetso.Aluminium le koporo li ka tšeloa oxidized ka mokhoa o ikhethileng nakong ea mocheso, tsa siea filimi e nang le nickel e ngata ka ntle ho lakane.Phello ena e bonahala ka ho khetheha holim'a terata e tšesaane kapa hlobo e nang le tekanyo e phahameng ea boima ba 'mele.Filimi ea makenete e tlosoa ka pickling kapa acid e khanyang leaching ho tsosolosa thepa e seng ea makenete ea thepa.Motsoako oa ho kenella ka tlase, matla a phahameng, le ho hanyetsa ho hotle ho hoholo ho sebelisitsoe lits'ebetsong tse ngata, haholo lisebelisoa tsa ho metha hantle le likarolo tsa elektroniki.

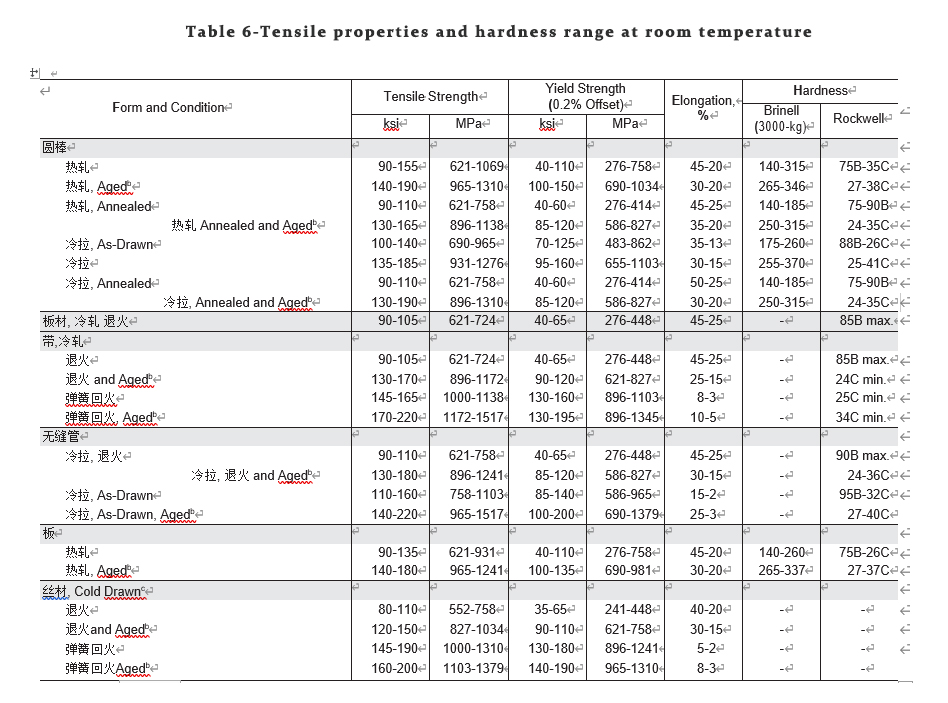

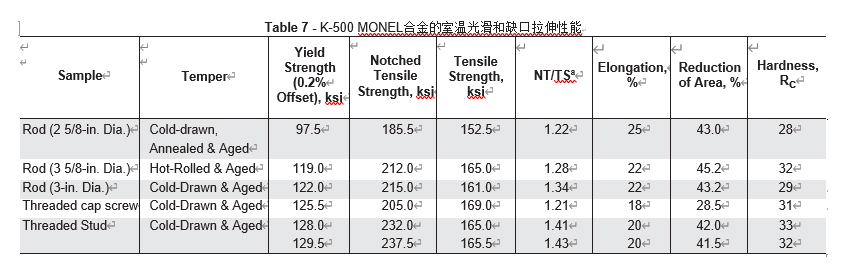

Ho fumanoe hore Monel alloy K-500 e na le botsitso bo botle haholo tekong ea nako e telele ea ho pepeseha le tlhahlobo ea potoloho.Thepa ena ea alloy e lumella hore e sebelisoe lisebelisoa tse phahameng tse nepahetseng tse kang gyros.Mofuta o ikhethileng oa thepa ea ho tsitsa le ho thatafala mochesong oa kamore e bonts'oa ho Lethathamo la 6. Likamano tse hakanyetsoang pakeng tsa thepa e tsitsitseng le boima ba li-bar le forgings li hlaha ho Feiga.4 le 5, 'me likamano tse tšoanang tsa maqephe le li-strip li hlaha ho Setšoantšo sa 6. Lethathamo la 7 le bapisa ts'ebetso ea notch ea mehlala e boreleli.Thepa ea nako e khuts'oane le mocheso o phahameng oa mocheso oa li-alloy bars tsa K500 tlas'a maemo a fapaneng a bontšoa setšoantšong se ka tlase.Lithupa tse chesang tse chesang li ile tsa lekoa ka lebelo la lisenthimithara tse 0,016 / min ka matla a lihlahisoa le 0,026 lisenthimithara / min ho tloha moo ho senya.Mehlala e huloang ke serame e ile ea lekoa ka matla a tlhahiso ea 0.00075 inch/min, e lateloa ke 0.075 inches/min.

K-500 Monel alloy e na le ts'ebetso e ntle haholo ea mocheso o tlase.Matla a tsitsitseng le matla a lihlahisoa a eketseha ka mocheso o fokotsehang, ha polasetiki le ho tiea li batla li sa amehe.Esita le lithempereichara tse tlaase joaloka haedrojene ea metsi, phetoho ea ho tloha ho thata ho ea ho e brittle ha e etsahale.Ka hona, motsoako o loketse lits'ebetso tse ngata tsa mocheso o tlase.Ts'ebetso ea K-500 alloy base base metal le weld sheet sheet ho -423 ° F e bonts'oa.Haeba phekolo ea botsofali e etsoa ka mor'a thepa ea ho cheselletsa annealing, weld e nang le matla a botsofali e thatafatsa tšepe ntle le tahlehelo e tebileng ea ductility e ka fumanoang.Ho chesoa ha thepa e thata ka lilemo ho lokela ho qojoa hobane ductility ea bona e fokotsehile haholo.

MONEL alloy K-500 e khethiloe e le UNS N05500 le Werkstoff NR.2.4375.E thathamisitsoe ho NACEMR-01-75 Oil and Gas Services.Alloy K-500 e fumaneha ka mefuta e mengata e fapaneng ea leloala le tloaelehileng ho kenyelletsa tube, tube, plate, strip, plate, round bar, flat bar, forgings, hexagon le terata.Plate, Sheet and Strip -BS3072NA18(Plate and strip),BS3073NA18(Strip),QQ-N-286(Plate, sheet and Strip),DIN 17750(Plate, Sheet and strip),ISO 6208(Sheet, Sheet and Strip) Mehala, Mehala, Lithapo le Mehala -BS3075NA18(Mohala), BS3076NA18(Thupa le molamu),ASTM B 865(Molamu le molamu),DIN 17752(Thupa le molamu),DIN 17753(Thapo),DIN 17754(Forgings),QQ -N-286(Thupa, Molamu, Mohala le Melamu), SAE AMS 4676(Lithupa le lithupa),ASME Code Case 1192(Rods and rods),ISO 9723(melamu),ISO 9724(Wire),ISO9725(Forgings) Tubes le Li-tubes -BS3074NA18(Li-tubes le li-tubes tse se nang moeli),DIN 17751(Li-tubes le li-tubes) Lihlahisoa tse ling -DIN 17743(Chemical Composition),SAE AMS 4676(Chemical composition),QQ-N-286(Motsoako oa lik'hemik'hale)

Nako ea poso: Sep-20-2022