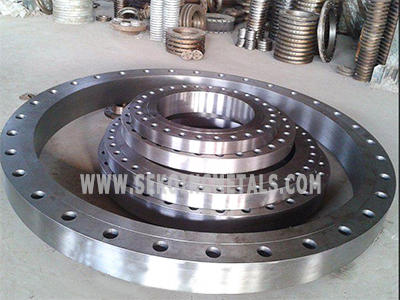

Inkoloy 825 Flange

Inkoloy 825 (W.Nr 2.4858) Flange

Lisebelisoa tsa Flange :Incoloy Alloy 825 (UNS N08825)

Mefuta ea Flange:Ho ea ka litlhoko tsa bareki

Letsatsi la thomello :Matsatsi a 15-30

Nako ea Tefo :T/T, L/C, Paypal, Ect

Sekoinc Metals Main e hlahisa le ho fana ka li-alloys tse khethehileng Flanges, re amohela taelo ea mohlala

Motsoako oa 825is the Theko e phahameng ea nickel e fana ka motsoako o sebetsang hantle oa khatello ea maikutlo ho corrosion cracking resistance.Corrosion resistance e ntle mefuteng e fapaneng ea mecha ea litaba, joalo ka sulfuric, phosphoric, nitric le organic acid, tšepe ea alkali joalo ka sodium hydroxide, hydroxide potassium le hydrochloric acid.

Ts'ebetso e phahameng ka kakaretso ea Incloy 825 e bonts'oa mokelikeli o tukang oa nyutlelie o nang le mefuta e fapaneng ea mecha ea litaba e senyang, joalo ka sulfuric acid, nitric acid le sodium hydroxide, kaofela li sebetsoa ka thepa e tšoanang.

| Alloy | % | Ni | Cr | Mo | Fe | C | Mn | Si | S | Cu | Al | Ti | P |

| 825 | Min. | 38.0 | 19.5 | 2.5 | 22.0 | - | - | - | - | 1.5 | 0.6 | - | |

| Max. | 46.0 | 23.5 | 3.5 | - | 0.05 | 1.0 | 0.5 | 0.03 | 3.0 | 0.2 | 1.2 | 0.03 |

| Botenya | 8.14 g/cm³ |

| Sebaka se qhibilihang | 1370-1400 ℃ |

| Boemo | Matla a tšepe Rm N/mm² | Ho hlahisa matla Rp 0. 2N/mm² | Elongation Joalo ka % | Ho thatafala ha Brinell HB |

| Phekolo ea tharollo | 550 | 220 | 30 | ≤200 |

• Mefuta ea Flange:

→ Flange ea poleiti ea welding (PL) → Slip-on Neck Flange (SO)

→ Welding molala flange (WN) → Integral flange (IF)

→ Socket welding flange (SW) → Moqomo oa likhoele (Th)

→ Lenonyeletso le nang le lenonyeletso (LJF) → Lenonyeletso le foufetseng (BL(li-)

♦ Lisebelisoa tse ka sehloohong tsa Flange tseo re li Hlahisang

• Ts'epe e sa beng le mabali :ASTM A182

Kereiti ea F304 / F304L, F316/ F316L,F310, F309, F317L,F321,F904L,F347

Duplex Stainless Steel: Kereiti ea F44 / F45 / F51 / F53 / F55 / F61 / F60

• Nickel Alloys : ASTM B472, ASTM B564, ASTM B160

Monel 400,Nickel 200, Incoloy 825, Incoly 926, Inconel 601, Inconel 718

Hastelloy C276, Alloy 31, Alloy 20, Inconel 625, Inconel 600

• Lisebelisoa tsa Titanium:Gr1/Gr2/Gr3/Gr4/GR5/Gr7/Gr9/Gr11/Gr12

♦ Maemo:

ANSI B16.5 Class150,300,600,900,1500(WN,SO,BL,TH,LJ,SW)

DIN2573,2572,2631,2576,2632,2633,2543,2634,2545(PL,SO,WN,BL,TH)

Inkoloy 825 Lihlahisoa tse Fumanehang ka Metals ea Sekonic

Ke hobane'ng ha Inkoloy 825?

825 alloy ke mofuta o mong oa motsoako o akaretsang oa boenjiniere, o nang le acid le alkali corrosion resistance ka oxidation le ho fokotsa tikoloho le ho hanyetsa ka katleho khatellong ea khatello ea maikutlo bakeng sa sebopeho sa eona se phahameng sa nickel. acid, phosphoric acid, nitric acid le organic acid, ho alkali, joalo ka sodium hvdroxide, potasiamo hvdroxide le tharollo ea hvdrochloric acid.Ts'ebetso e felletseng ea 825 alloy e bonts'a mokelikeli o tukang oa nyutlelie oa mefuta e fapaneng ea kutu, joalo ka asiti ea sulfuric, asiti ea nitric le sodium hvdroxide kaofela li sebetsoa ka sesebelisoa se le seng.

•Ho hanyetsa hantle khatello ea kelello corosion cracking.

•Ho hanyetsana hantle le pitting le crevice corrosion

•Ho hanyetsa hantle ho oxidization le non oxidizing acid.

•Lisebelisoa tse ntle tsa mochini mocheso oa kamore kapa ho fihla ho 550 ℃

•Setifikeiti sa sekepe sa khatello ea tlhahiso ea 450 ℃

Incoloy 825 Sebaka sa kopo:

•Likarolo tse kang li-coil tse futhumatsang, litanka, likhreiti, libaskete le liketane ka har'a limela tsa pickling tsa sulfuric acid.

•Lisebelisoa tsa mocheso tse pholileng ka metsi a leoatle, lisebelisoa tsa lipeipi tsa lihlahisoa tsa leoatle;li-tubes le likarolo tsa tšebeletso ea khase e bolila

•Lisebelisoa tsa mocheso, li-evaporators, scrubbers, liphaephe tsa ho qoelisa joalo-joalo tlhahisong ea asiti ea phosphoric.

•Mocheso o pholileng ka moea libakeng tse hloekisang peterole

•Ho lokisa lijo

•Semela sa lik'hemik'hale