Haynes25 alloy e hanyetsanang le mocheso o phahameng

Haynes25 alloy e hanyetsanang le mocheso o phahameng,

Haynes25 sebopeho, L605, tshebetso, R30605,

Mabitso a Tloaelehileng a Khoebo: Haynes 25, AlloyL605, Cobalt L605,GH5605, Udimet L605, UNSR30605

Haynes 25(AlloyL605) ke tharollo e tiileng e matlafalitsoeng cobalt-chromium-tungsten nickel alloy e nang le matla a matla a mocheso o phahameng le ho hanyetsa oxidation ho 2000 ° F (1093 ° C).Alloy e boetse e fana ka khanyetso e ntle ea sulfidation le ho hanyetsa ho apara le ho tsuba.Alloy L-605 e na le thuso lits'ebetsong tsa turbine ea khase joalo ka mehele, li-blades le likarolo tsa kamore e tukang (masela a masela) hape e ka sebelisoa lits'ebetsong tsa sebōpi sa indasteri joalo ka li-muffles kapa li-liner ka litofong tsa mocheso o phahameng.

Haynes 25 (Alloy L605) Sebopeho sa Lik'hemik'hale

| C | Cr | Ni | Fe | W | Co | Mn | Si | S | P |

| 0.05-0.15 | 19.0-21.0 | 9.0-11.0 | ≦3.0 | 14.0-16.0 | tekatekano | 1.0-2.0 | ≦0.4 | ≦0.03 | ≦0.04 |

Haynes 25(Alloy L605) Thepa ea 'Mele

| Botenya (g/cm3) | Sebaka se qhibilihang (℃) | Matla a khethehileng a mocheso (J/kg·℃) | Restivity ea motlakase (Ω·cm) | Thermal conductivity (W/m·℃) |

| 9.27 | 1300-1410 | 385 | 88.6×10E-6 | 9.4 |

Haynes 25(Alloy L605) Mechanical Properties

Representative Tensile Properties, Sheet

| Mocheso, °F | 70 | 1200 | 1400 | 1600 | 1800 |

| Ultimate Tensile Matla, ksi | 146 | 108 | 93 | 60 | 34 |

| 0.2% Matla a Puno, ksi | 69 | 48 | 41 | 36 | 18 |

| Elongation,% | 51 | 60 | 42 | 45 | 32 |

Mathata a Tloaelehileng a Khatello ea Maikutlo

| Mocheso, °F | 1200 | 1400 | 1500 | 1600 | 1700 | 1800 |

| Lihora tse 100, ksi | 69 | 36 | 25 | 18 | 12 | 7 |

| Lihora tse 1 000, ksi | 57 | 26 | 18 | 12 | 7 | 4 |

Haynes 25(Alloy L605) Maemo le Litlhaloso

AMS 5537, AMS 5796,EN 2.4964,GE B50A460,UNSR30605,Werkstoff 2.4964

| Bara/Molamu | Mohala / Welding | Hlobola/Koala | Leqephe/Letlapa | Pipe/Tube |

| AMS 5537 | AMS 5796/5797 | AMS 5537 | AMS 5537 | - |

Haynes 25(Alloy L605) Lihlahisoa tse fumanehang ka Metals ea Sekonic

Alloy L605 Bars & Rods

Li-bars tse chitja/Flat bars/Hex bars, Size From 8.0mm-320mm, E sebelisetsoa liboutu, li-fastners le likarolo tse ling

Alloy L605 terata ea ho tjheseletsa

Fana ka terata ea welding le terata ea selemo ka mokhoa oa khoele le bolelele bo sehiloeng.

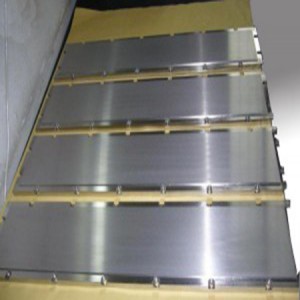

Alloy L605 lakane le poleiti

Bophara ho fihla ho 1500mm le bolelele ho fihla ho 6000mm, Botenya ho tloha 0.1mm ho isa 100mm.

Alloy L605 Gasket/ Ring

Dimension e ka etsoa ka mokhoa o ikhethileng ka sefahleho se khanyang le mamello e nepahetseng.

Alloy L605 strip & coil

Boemo bo bonolo le boemo bo thata bo nang le bokaholimo bo khanyang ba AB, bophara ho fihla ho 1000mm

Hobaneng Inconel Haynes 25(Alloy L605) ?

•Matla a ikhethang a mocheso o phahameng

•Oxidation e hanyetsana le 1800°F

•Ha e khone ho lla

•E hanyetsana le libaka tsa leoatle, li-acids le maro a 'mele

Haynes 25(Alloy L605) Sebaka sa kopo:

•Likarolo tsa enjene ea turbine ea khase joalo ka likamore tse tukang le li-afterburners

•Mocheso o phahameng oa li-ball bearings le mabelo a ho jara

•Lithaba

•Li-valve tsa pelo

Haynes 25 alloy ke motsoako oa cobalt-nickel-cr-w o nang le - matla a mocheso o phahameng le -1800 ° F (980 ° C) tikoloho ea oxidation, ho pepeseha nako e telele, le - vulcanization resistance. E ka etsoa le ho bōptjoa ka mekhoa e tloaelehileng 'me e na le e 'nile ea sebelisoa bakeng sa ho lahla likarolo.Likarolo tse ling tse khahlehang li kenyelletsa ho hanyetsa ho roala le ho taboha holim'a litšepe.Sebopeho sa sehlahisoa se fumanehang: Lisebelisoa li hlahisoa ka mokhoa oa lipoleiti, maqephe, likhoele, li-billet, lithupa, lithapo, li-electrode tse koahetsoeng, li-tubes le li-tubes. : Haynes 25 Alloy e ile ea rehoa R30605.Libara, litšepe, Lithapo le Lithapo: AMS 5759 (libare, mehele le li- forging), Lipampiri, lipampiri le likhoele: AMS 5537 (Lishiti, lipampiri le lipampiri) Tse ling: AMS 5796 (Wire) le AMS 5797 (Li-electrode tse Coated Welding)