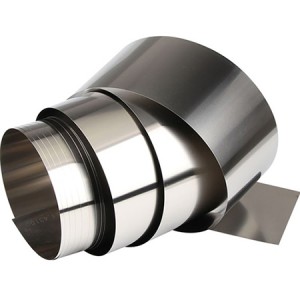

4J29-Kovar alloy strip ea Kovar bar / kovar sheet / kovar tube

Mabitso a Tloaelehileng a Khoebo: Kovar Alloy,4J29,UNS K94610(FeNi29Co17),29HК Kovar,KV-1,29HК-BИ,Werkstoff Nr.1.3981

Alloy ena e boetse e khabisitse Glass e tiisitsoeng le ho laola katoloso ea alloy,Motsoako o na le alinear katoloso coefficiente tšoanang le ea silicon boron khalase e thata ka 20-450 ° C, antlha e phahameng ea Curie, le botsitso bo botle ba sebopeho sa mocheso o tlase.Filimi ea oxide ea alloy e teteaneng ebile e ka ba hantlekolobisitsoekakhalase.Ha e kopane le mercury mme e loketse ho sebelisoa ho limithara tsa ho lahla tse nang le mercury.Ke sesebelisoa sa mantlha sa ho tiisa bakeng sa lisebelisoa tsa vacuum tsa motlakase.

| C | Cr | Ni | Mo | Si | Mn | P | S | Fe | Co | Cu |

| ≤0.03 | ≤0.2 | 28.5-29.5 | ≤0.2 | ≤0.3 | ≤0.5 | ≤0.02 | ≤0.02 | tekatekano | 16.8-17.8 | ≤0.2 |

| Boima ba 'mele(g/cm3) | Thermal conductivity(W/m·K) | Ho hanyetsa motlakase(μΩ·cm) |

| 8.3 | 17 | 45 |

| Alloy Grades

| Kakaretso ea katoloso coefficient a,10-6/ oC | |||||||

| 20-200 oC | 20-300 oC | 20-400 oC | 20-450 oC | 20-500 oC | 20-600 oC | 20-700 oC | 20-800 oC | |

| kovar | 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 |

Katoloso e mahareng ya khoevevevene ya melata moleng

| Alloy Grades | Setšoantšo sa tsamaiso ea mocheso oa mocheso | Kakaretso ea katoloso coefficient α,10-6/ oC | ||

| Kovar | 20-300 oC | 20-400 oC | 20-450 oC | |

| Sebakeng sa haedrojene se futhumetse ho 900 ± 20 oC, ho kenella ka 1h, ebe se futhumatsoa ho 1100 ± 20 oC, ho kenella ka metsotso e 15 ho isa ho 5 oC / min sekhahla sa pholileng ho ea ka tlase ho 200 oC se lokollotsoe. | ----- | 4.6-5.2 | 5.1-5.5 | |

Kovar e tloaelehileng ea ho atolosa coefficient

| Alloy Grades | Kakaretso ea katoloso coefficient a,10-6/ oC | |||||||

| Kovar | 20-200oC | 20-300 oC | 20-400oC | 20-450oC | 20-500oC | 20-600oC | 20-700oC | 20-800oC |

| 5.9 | 5.3 | 5.1 | 5.3 | 6.2 | 7.8 | 9.2 | 10.2 | |

Lihlahisoa tsa Kovar Alloy tse fumanehang ka Metals ea Sekonic

Ke hobane'ng ha Inconel Kovar ?

1.Kovar e na le tšebeliso e pharaletseng indastering ea lisebelisoa tsa elektronike, tse kang likarolo tsa tšepe tse kopantsoeng le lienfelopo tsa khalase e thata.Likarolo tsena li sebelisetsoa lisebelisoa tse kang li-tubes tsa matla le X-ray tubes, joalo-joalo.

2.Ka indasteri ea semiconductor kovar e sebelisoa ka har'a liphutheloana tse tiisitsoeng ka hermetically bakeng sa lisebelisoa tse kopantsoeng le tse sa tloaelehang tsa potoloho.

3.Kovar e fanoa ka mefuta e sa tšoaneng ho etsa hore ho be bonolo ho etsa lihlahisoa tse sa tšoaneng tsa tšepe.E na le litšobotsi tsa ho atolosa mocheso tse tšoanang le tsa khalase e thata.E sebelisoa bakeng sa manonyeletso a ho atolosa a tšoanang pakeng tsa tšepe le likhalase kapa lirafshoa.

4.Kovar alloy ke vacuum e qhibilihisitsoeng, tšepe-nickel-cobalt, alloy e fokolang ea ho atolosa eo lik'hemik'hale tsa eona li laoloang ka har'a meeli e moqotetsane ho netefatsa thepa e nepahetseng ea ho atolosa mocheso.Litaolo tse pharalletseng tsa boleng li sebelisoa ha ho etsoa alloy ena ho netefatsa thepa e ts'oanang ea 'mele le ea mochini bakeng sa bonolo ho taka, ho hatakela le ho sebetsa ka machining.

Sebaka sa kopo ea Kovar Alloy:

● Kovar alloy e 'nile ea sebelisoa ho etsa litiiso tsa hermetic ka likhalase tsa Pyrex tse thata le lisebelisoa tsa ceramic.

● Alloy ena e fumane ts'ebeliso e pharaletseng ho li-tubes tsa matla, li-microwave tubes, transistors le diode.Lipotolohong tse kopaneng, e 'nile ea sebelisoa bakeng sa pakete e bataletseng le sephutheloana sa li-in-line tse peli.