17-4PH thupa e sa hloekang,

17-4PH thupa e sa hloekang,

05Cr17Ni4Cu4Nb, 0Cr17Ni4Cu4Nb, 17-4phBars, S51740, SUS630,

Mabitso a Tloaelehileng a Khoebo: 17-7PH,SUS631,S17700,07Cr17Ni7Al,W.Nr.1.4568

17-7PH ke austenitic-martensitic precipitation e thatafatsa tšepe e sa hloekang e entsoeng motheong oa 18-8CrNi, eo hape e tsejoang e le karolo e laoloang ea phetoho ea tšepe e sa hloekang. Ha e le tharollo ea ho phekola mocheso, 1900 ° F, tšepe e na le austenitic empa e fetoha phetoho ho ea tlaase- sebopeho sa carbon martensitic nakong ea pholileng ho mocheso oa kamore.Phetoho ena ha e fele ho fihlela mocheso o theohela ho 90°F.Ho futhumatsa ho latelang ho mocheso oa 900-1150 ° F bakeng sa hora e le 'ngoe ho isa ho tse' nè pula e matlafatsa motsoako.Kalafo ena e thata e boetse e halefisa sebopeho sa martensitic, ho eketsa ductility le ho tiea

17-7PH Sebopeho sa Lik'hemik'hale

| C | Cr | Ni | Si | Mn | P | S | Al |

| ≤0.09 | 16.0-18.0 | 6.5-7.75 | ≤1.0 | ≤1.0 | ≤0.04 | ≤0.03 | 0.75-1.5 |

17-7PH Thepa ea 'Mele

| Boima ba 'mele (g/cm3) | Sebaka sa ho qhibiliha (℃) |

| 7.65 | 1415-1450 |

17-7PH Thepa ea Mechini

| Boemo | бb/N/mm2 | б0.2/N/mm2 | δ5/% | ψ | HRW | |

| Phekolo ea tharollo | ≤1030 | ≤380 | 20 | - | ≤229 | |

| Pula e thatafatsa | 510 ℃ botsofali | 1230 | 1030 | 4 | 10 | ≥383 |

| 565℃botsofali | 1140 | 960 | 5 | 25 | ≥363 | |

17-7PH Melao le Litlhaloso

AMS 5604, AMS 5643, AMS 5825,ASME SA 564, ASME SA 693, ASME SA 705, ASME Type 630,ASTM A 564, ASTM A 693, ASTM A 705, ASTM Type 630

Boemo A – H1150,ISO 15156-3,NACE MR0175,S17400,UNS S17400,W.Nr./EN 1.4548

| Bara/Molamu | Mohala | Hlobola/Koala | Leqephe/Letlapa | Pipe/Tube |

17-7PH Lihlahisoa tse Fumanehang ka Metals ea Sekonic

17-7PH Libara le Lithupa

Li-bars tse chitja/Flat bars/Hex bars, Size From 8.0mm-320mm, E sebelisetsoa liboutu, li-fastners le likarolo tse ling

17-7PH Mohala

Fana ka terata ea welding le terata ea selemo ka mokhoa oa khoele le bolelele bo sehiloeng.

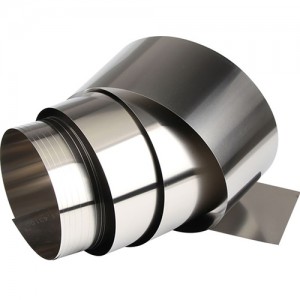

17-7PH lakane & poleiti

Bophara ho fihla ho 1500mm le bolelele ho fihla ho 6000mm, Botenya ho tloha 0.1mm ho isa 100mm.

17-7PH seamless tube & welded pipe

Boholo ba litekanyetso le boholo bo hlophisitsoeng bo ka hlahisoa ke rona ka mamello e nyane

17-7PH e hlobolisa & khola

Boemo bo bonolo le boemo bo thata bo nang le bokaholimo bo khanyang ba AB, bophara ho fihla ho 1000mm

17-7PH Fasteners

Lisebelisoa tsa 17-7PH ka mefuta ea Bolts, screws, flanges le tse ling tse potlakileng, ho latela litlhaloso tsa bareki.

Hobaneng 17-7 PH?

•Matla a phahameng a tsitsipano le boima ba ho fihla ho 600°F

•E thibela ho bola

•Khanyetso e ntle ea oxidation hoo e ka bang 1100°F

•Matla a ho phunyeha ho fihla ho 900°F

17-7 PHAPITISE Sebaka:

•Li-valve tsa heke

•Lisebelisoa tsa ho lokisa lik'hemik'hale

•Li-pump shafts, likere, li-plungers

•Li-valve stems, libolo, lihlahla, litulo

•Li-fasteners

17-4PH Tšimo ea kopo: Li-platform tsa kantle ho naha, mokato oa helikopta, lipolanete tse ling.Indasteri ea lijo.Indasteri ea pampiri le pampiri.Sebaka (lehare la turbine).Likarolo tsa mochini.Libarele tsa litšila tsa nyutlelie.